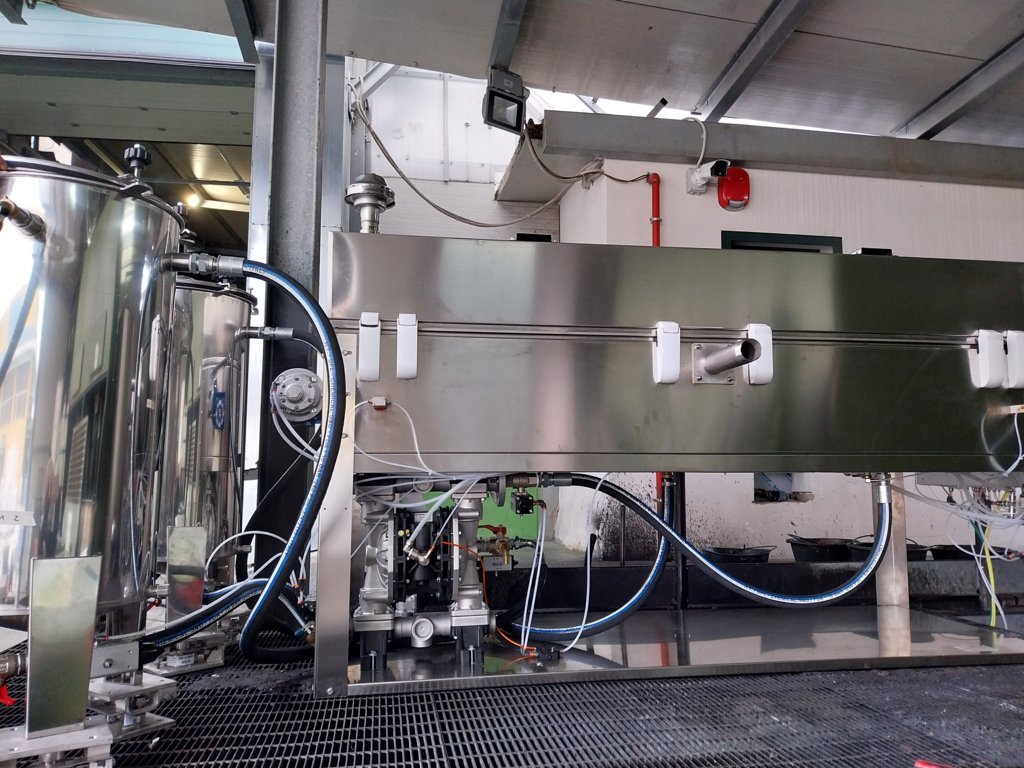

SIRIUS ultrasonic washing tank

The SIRIUS washing tank is a system designed for cleaning small, medium and large anilox/sleeves used in label printing, flexographic printing and gravure printing.

SIRIUS features an ultrasonic system consisting of piezoelectric heads contained in submersible transducers.

The transducers are inserted in modules at the bottom of the tank, so as to facilitate maintenance or possible partial use of the tank.

But let’s look in detail at how SIRIUS works and what are its advantages over other ultrasound implants on the market.

How does ultrasonic washing work?

The washing principle of SIRIUS is based on ultrasonic technology with the principle of multifrequency, a technology developed to achieve high protection of parts during washing.

SIRIUS uses a very simple principle: cylinders are partially submerged in a tank (not underneath) with a product consisting of water and detergent. We are talking about generally alkaline detergents.

The cylinder is set into rotation, and the immersibles, cavitation wave boxes that take advantage of the liquid and distribute and transmit it within the anilox cells, are activated.

Ultrasound thus cleans cells clogged by inks.

A holding tank positioned on the front of the washing machine allows the rinsing operation to be carried out easily.

Why ultrasound?

There are several technologies on the market for cleaning ceramic printing cylinders.

Bicarbonate cleaning technology, which almost no one uses anymore because it is very aggressive and corrosive, almost like sandblasting performed on cylinders. It is very dirty in-house and not very reliable.

In contrast,high pressure uses mains water, which cleans the cells with a 150-bar jet. Of all these technologies, high pressure is definitely the greenest.

Ultrasonic washing is a less green choice, but this water bath and alkaline detergent has the advantage of an extremely longer service life, and a lower disposal cost.

Why choose SIRIUS?

Compared with conventional ultrasonic cleaning systems on the market, SIRIUS has an undeniable advantage.

The installed watertight submersibles, which house the transducers welded inside them, are independent of each other.

If a transducer breaks, you pull out the only module that can be repaired, and in the meantime the tank does not stop and cleans one half of the cylinder at a time. This prevents harmful downtime and makes maintenance operations easier.

If you would like more information about how SIRIUS ultrasonic washing works, please contact us!

Share

Stai cercando un produttore di distillatori per acqua, solvente e impianti di lavaggio?